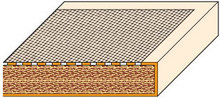

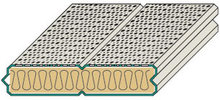

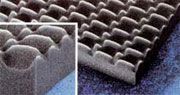

It is a load bearing monolithic panel that can be employed, for its characteristics, in building soundproofing and sound absorbing cabins for operating machines, partition walls and casings to be installed directly on the structure of noisy machines. Trialfon 80 is composed of two pressure bended metal sheets with an interposed mineral wool with orientated fibers, glued and hot-pressed. The side exposed to the noise is made from perforated metal sheet while

the exterior is smooth and can be made in pre-varnished steel, galvanized steel, stainless steel, aluminum, etc.

- It can be used in combination with the slatted Diapason system.

- It is fire (class 1) and corrosion resistant.

- It does not absorb moisture and dust.

- It does not contain asbestos and is reliable over time.

- It is available in four different thicknesses: 40 mm / 60/80/100.